USD

- USD

- CNY

- HKD

- EUR

English

- العربية

- čeština

- dansk

- Deutsch

- Ελληνικά

- English

- Español

- Français

- ic

- Italiano

- Netherlands

- norsk Språk

- język polski

- pt

- Português

- 中文

Pneumatic cylinders Price List

| Model | Description | Leading | Price |

|---|---|---|---|

|

ISO 21287

Up to 50% less installation space than comparable standards-based cylinders to ISO 15552

Good running performance and long service life

|

In Stock

|

Subscribe

|

|

|

Product weight844 gType of mountingWith through-holeVia female threadWith accessoriesEither:Pneumatic connectionG1/8Note on materialsRoHS-compliantMaterial collar screwsSteelMaterial coverAnodised wrought aluminium alloyMaterial sealsTPE-U(PUR)Material piston rodHigh-alloy steelMaterial cylinder barrelSmooth-anodised wrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Stroke30 mm

Piston diameter50 mm

Piston rod threadM12x1.25

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

Conforms to standardISO 21287

Piston-rod endMale thread

Position detectionVia proximity switch

Symbol00991217

VariantsPiston rod at one end

Operating pressure0.06 MPa ... 1 MPa

Operating pressure0.6 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-20 °C ... 80 °C

Impact energy in end positions1 J

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke1057 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke1178 N

Moving mass212 g

Product weight685 g

Type of mountingWith through-hole Via female thread With accessories Either:

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material collar screwsSteel

Material coverAnodised wrought aluminium alloy

Material sealsTPE-U(PUR)

Material piston rodHigh-alloy steel

Material cylinder barrelSmooth-anodised wrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Position detectionVia proximity switchSymbol00991217VariantsPiston rod at one endOperating pressure0.1 MPa ... 1 MPaOperating pressure1 bar ... 10 barOperating pressure14.5 psi ... 145 psiOperating mediumCompressed air to ISO 8573-1:2010 [7:4:4]Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)Corrosion resistance class CRC2 - Moderate corrosion stressLABS (PWIS) conformityVDMA24364-B1/B2-LAmbient temperature-20 °C ... 80 °CImpact energy in end positions0.14 JTheoretical force at 0.6 MPa (6 bar, 87 psi), return stroke141 NTheoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke188 NMoving mass for 0 mm stroke20 gAdditional moving mass per 10 mm stroke6 gBasic weight for 0 mm stroke149 gAdditional weight per 10 mm stroke23 gType of mountingEither:With through-holeWith accessoriesPneumatic connectionM5Material collar screwsGalvanised steelMaterial coverWrought aluminium alloyMaterial dynamic sealsNBRTPE-U(PU)Material piston rodHigh-alloy stainless steelMaterial cylinder barrelWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Ambient temperature-20 °C ... 80 °CImpact energy in end positions0.14 JTheoretical force at 0.6 MPa (6 bar, 87 psi), return stroke141 NTheoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke188 NMoving mass for 0 mm stroke20 gAdditional moving mass per 10 mm stroke6 gBasic weight for 0 mm stroke149 gAdditional weight per 10 mm stroke23 gType of mountingWith through-holeWith accessoriesEither:Pneumatic connectionM5Material collar screwsGalvanised steelMaterial coverWrought aluminium alloyMaterial dynamic sealsNBRTPE-U(PU)Material piston rodHigh-alloy stainless steelMaterial cylinder barrelWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Corrosion resistance class CRC2 - Moderate corrosion stressLABS (PWIS) conformityVDMA24364-B1/B2-LAmbient temperature-20 °C ... 80 °CImpact energy in end positions0.52 JTheoretical force at 0.6 MPa (6 bar, 87 psi), return stroke686 NTheoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke754 NMoving mass for 0 mm stroke63 gAdditional moving mass per 10 mm stroke9 gBasic weight for 0 mm stroke433 gAdditional weight per 10 mm stroke59 gType of mountingWith through-holeWith accessoriesEither:Pneumatic connectionG1/8Material collar screwsGalvanised steelMaterial coverWrought aluminium alloyMaterial dynamic sealsNBRTPE-U(PU)Material piston rodHigh-alloy steelMaterial cylinder barrelWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Stroke1 mm ... 200 mm

Piston diameter12 mm

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

Mode of operationDouble-acting

Piston-rod endFemale thread

DesignPiston Piston rod

Position detectionVia proximity switch

Symbol00991217

VariantsPiston rod at one end

Operating pressure0.12 MPa ... 1 MPa

Operating pressure1.2 bar ... 10 bar

Operating pressure17.4 psi ... 145 psi

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-20 °C ... 80 °C

Impact energy in end positions0.07 J

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke51 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke68 N

Moving mass for 0 mm stroke8 g

Additional moving mass per 10 mm stroke2 g

Basic weight for 0 mm stroke87 g

Additional weight per 10 mm stroke15 g

Type of mountingEither: With through-hole With accessories

Pneumatic connectionM5

Material collar screwsHigh-alloy stainless steel

Material coverWrought aluminium alloy

Material dynamic sealsNBR TPE-U(PU)

Material piston rodHigh-alloy stainless steel

Material cylinder barrelWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

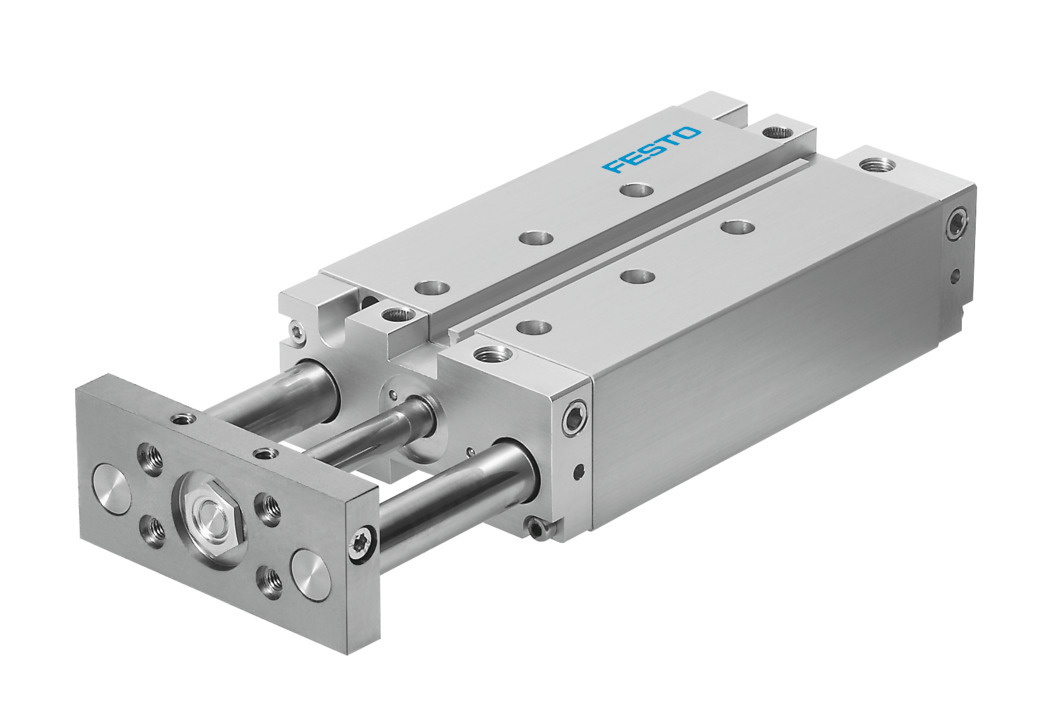

Piston rod secured against rotation by a guide rod and yoke platePlain bearingOptionally with through piston rod

|

In Stock

|

Subscribe

|

|

|

Corrosion resistant against aggressive ambient conditionsEasy-to-clean designLong service life thanks to optional dry-running seal

|

In Stock

|

Subscribe

|

|

|

SizeM20x1.5

Mounting positionoptional

Based on standardISO 8140

Threaded connectionFemale thread M20x1.5

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B2-L

Suitability for the production of Li-ion batteriesMetals with more than 5% by mass of copper, zinc or nickel by mass are excluded from use. Exceptions are nickel in steel, chemically nickel-plated surfaces, printed circuit boards, cables, electrical plug connectors and coils

Ambient temperature-40 °C ... 150 °C

Max. load capacity9 kN

Product weight757.8 g

Material rod clevisHigh-alloy steel

Note on materialsRoHS-compliant

Material boltHigh-alloy steel

Material nutHigh-alloy steel

Material lockHigh-alloy steel

|

In Stock

|

Subscribe

|

|

|

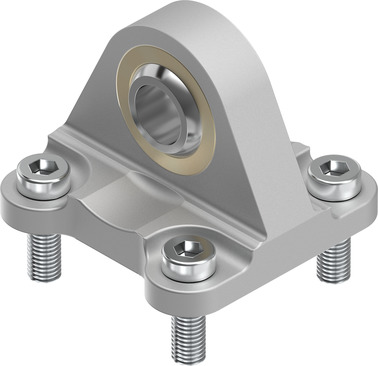

SizeM8Based on standardISO 12240-4Corrosion resistance class CRC3 - high corrosion stressLABS (PWIS) conformityVDMA24364-B2-LSuitability for the production of Li-ion batteriesMetals with more than 5% by mass of copper, zinc or nickel by mass are excluded from use. Exceptions are nickel in steel, chemically nickel-plated surfaces, printed circuit boards, cables, electrical plug connectors and coilsAmbient temperature-40 °C ... 150 °CProduct weight55 gNote on materialsRoHS-compliantMaterial of outer ringHigh-alloy steelMaterial housingHigh-alloy steelMaterial of inner racewayHigh-alloy steelMaterial nutHigh-alloy steel

|

In Stock

|

Subscribe

|

|

|

Size40

Based on standardISO 15552 (previously also VDMA 24562, ISO 6431, NF E49 003.1, UNI 10290)

VariantsHigh corrosion protection

Corrosion resistance class CRC4 - Very high corrosion stress

LABS (PWIS) conformityVDMA24364-B2-L

Suitability for the production of Li-ion batteriesMetals with more than 5% by mass of copper, zinc or nickel by mass are excluded from use. Exceptions are nickel in steel, chemically nickel-plated surfaces, printed circuit boards, cables, electrical plug connectors and coils

Ambient temperature-40 °C ... 150 °C

Max. load capacity1.5 kN

Product weight239 g

Note on materialsRoHS-compliant

Material mountingHigh-alloy stainless steel

Material rod end bearingPTFE Stainless steel

Material screwsHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

Stroke20 mm ... 400 mm

Piston diameter25 mm

Operating mode, drive unitYoke

CushioningElastic cushioning rings/plates at both ends Pneumatic cushioning, adjustable at both ends Shock absorber, soft characteristic curve

Mounting positionoptional

GuidePlain-bearing guide Recirculating ball bearing guide

DesignGuidance

Position detectionVia proximity switch

VariantsHeat-resistant seals max. 120°C

Operating pressure0.15 MPa ... 1 MPa

Operating pressure1.5 bar ... 10 bar

Mode of operationDouble-acting

CE mark (see declaration of conformity)To EU Explosion Protection Directive (ATEX)

UKCA marking (see declaration of conformity)To UK EX instructions

Explosion protectionZone 1 (ATEX) Zone 2 (ATEX)

ATEX category gasII 2G

Explosion ignition protection type for gasEx h IIC T4 Gb

Explosion ambient temperature-20 °C

|

In Stock

|

Subscribe

|

|

|

Stroke1 mm ... 8500 mm

Piston diameter32 mm

CushioningPneumatic cushioning, adjustable at both ends

Mounting positionoptional

Position detectionVia proximity switch

VariantsSupply port at both ends Standard piston Extended piston

Operating pressure0.2 MPa ... 0.8 MPa

Operating pressure2 bar ... 8 bar

Mode of operationDouble-acting

CE mark (see declaration of conformity)To EU Explosion Protection Directive (ATEX)

UKCA marking (see declaration of conformity)To UK EX instructions

Explosion protectionZone 1 (ATEX) Zone 2 (ATEX) Zone 22 (ATEX)

ATEX category gasII 2G

ATEX category dustII 3D

Explosion ignition protection type for gasEx h IIC T4 Gb X

Explosion ignition protection type for dustEx h IIIC T120°C Dc X

Explosion ambient temperature-10 °C

|

In Stock

|

Subscribe

|

|

|

Stroke1 mm ... 8500 mm

Piston diameter25 mm

CushioningPneumatic cushioning, adjustable at both ends

Mounting positionoptional

Position detectionVia proximity switch

VariantsSupply port at both ends Standard piston Extended piston

Operating pressure0.2 MPa ... 0.8 MPa

Operating pressure2 bar ... 8 bar

Mode of operationDouble-acting

CE mark (see declaration of conformity)To EU Explosion Protection Directive (ATEX)

UKCA marking (see declaration of conformity)To UK EX instructions

Explosion protectionZone 1 (ATEX) Zone 2 (ATEX) Zone 22 (ATEX)

ATEX category gasII 2G

ATEX category dustII 3D

Explosion ignition protection type for gasEx h IIC T4 Gb X

Explosion ignition protection type for dustEx h IIIC T120°C Dc X

Explosion ambient temperature-10 °C

|

In Stock

|

Subscribe

|

|

|

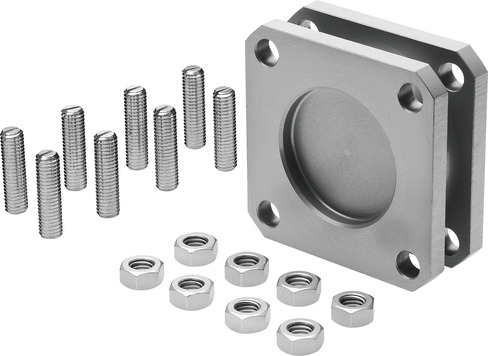

Size63

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-40 °C ... 150 °C

Product weight387 g

Note on materialsRoHS-compliant

Material mountingWrought aluminium alloy

Material threaded pinSteel Galvanised

Material nutSteel Galvanised

|

In Stock

|

Subscribe

|

|

|

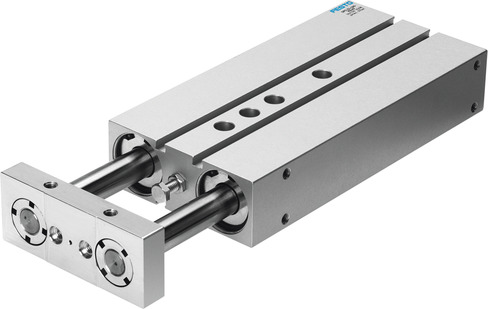

Distance from centre of gravity of load to yoke plate xs0 mm

Stroke100 mm

Adjustable end-position range/length10 mm

Piston diameter20 mm

Operating mode, drive unitYoke

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

GuidePlain-bearing guide

DesignGuidance

Position detectionVia proximity switch

Symbol00991249

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-20 °C ... 80 °C

Impact energy in end positions0.2 J

Max. effective load dependent upon stroke at defined distance xs11 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke282 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke376 N

alternative connectionsSee product drawing

Pneumatic connectionM5

Material coverWrought aluminium alloy

Material sealsNBR

Material housingWrought aluminium alloy

Material piston rodHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

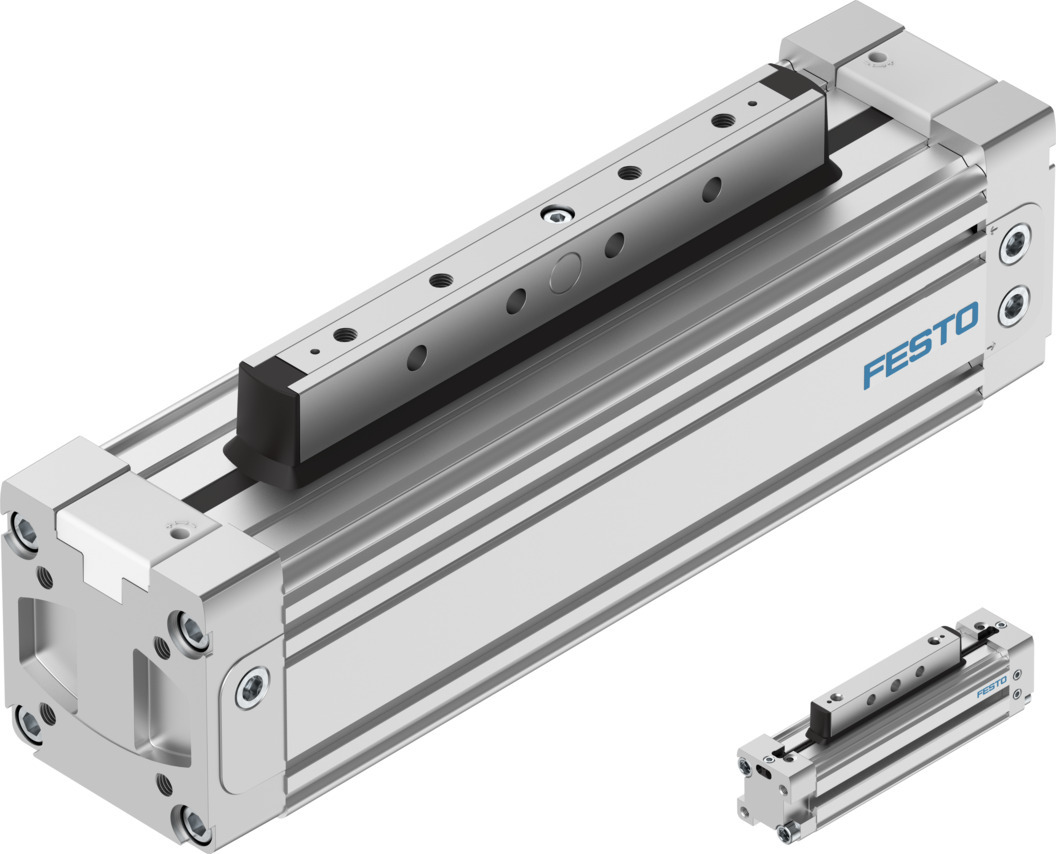

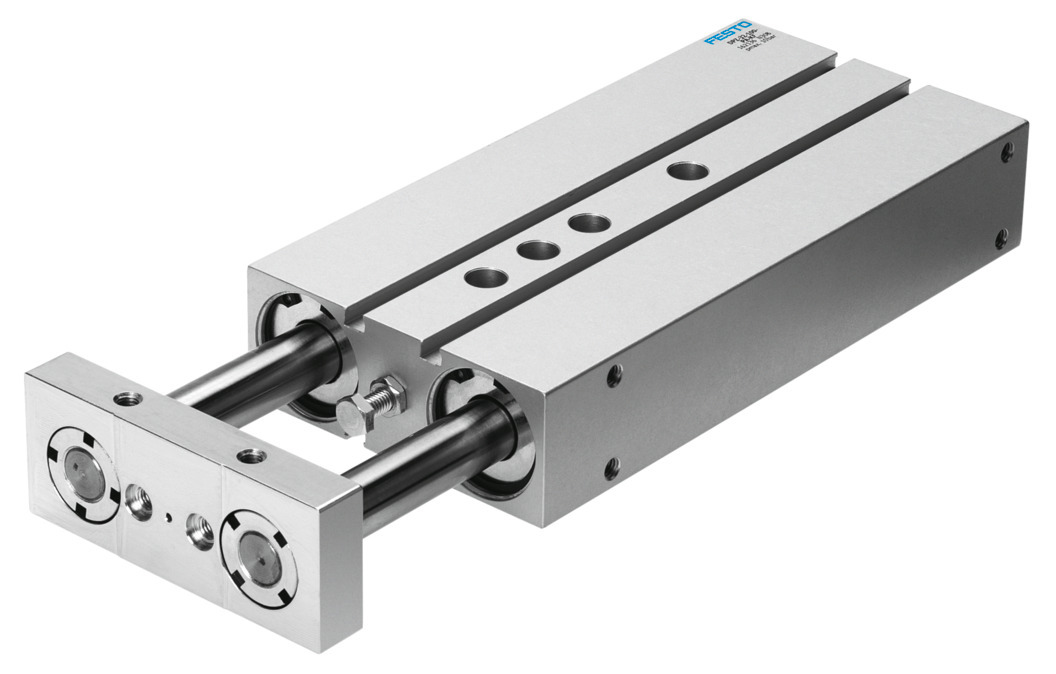

Stroke100 mm

Adjustable end-position range/length10 mm

Piston diameter25 mm

Operating mode, drive unitYoke

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

GuideRecirculating ball bearing guide

DesignGuidance

Position detectionVia proximity switch

Symbol00991249

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC0 - No corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-20 °C ... 80 °C

Impact energy in end positions0.3 J

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke452 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke590 N

alternative connectionsSee product drawing

Pneumatic connectionM5

Material coverWrought aluminium alloy

Material sealsNBR

Material housingWrought aluminium alloy

Material piston rodCase-hardened steel

|

In Stock

|

Subscribe

|

|

|

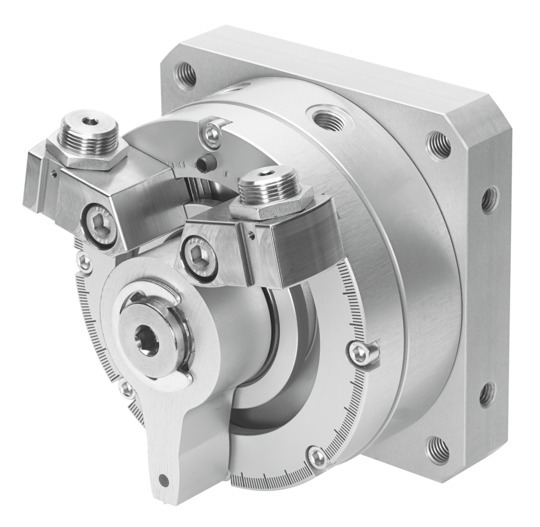

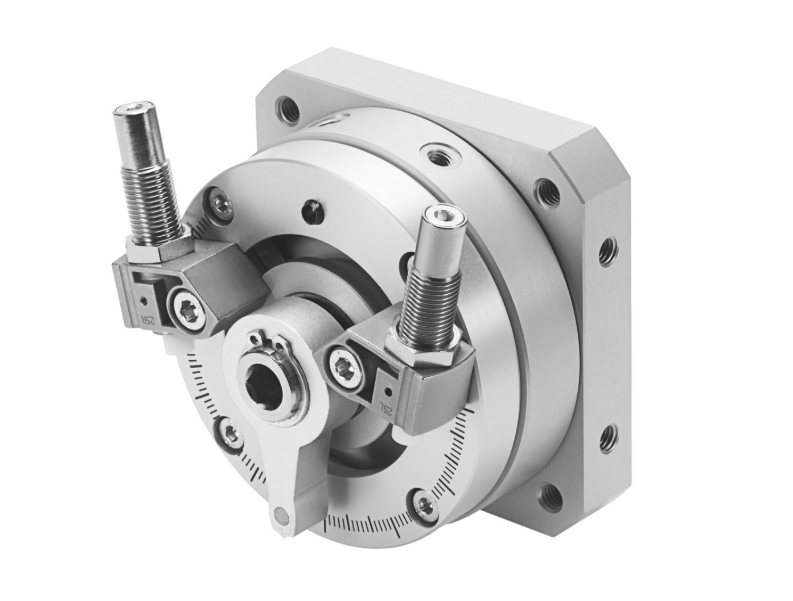

Twin-piston drive, power transmission via rack and pinion principlePremium drive for very high energy absorption (load capacity and speed)Very high precision and long service life

|

In Stock

|

Subscribe

|

|

|

Size25

Cushioning angle33 deg

Setting range of swivel angle for each end position+10/-100 deg

Swivel angle180 deg

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

DesignRack and pinion

Position detectionVia proximity switch

Symbol00991265

Operating pressure0.3 MPa ... 0.8 MPa

Operating pressure3 bar ... 8 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

LABS (PWIS) conformityVDMA24364 zone III

Ambient temperature-10 °C ... 60 °C

Theoretical torque at 0.6 MPa (6 bar, 87 psi)5.15 Nm

Permissible mass moment of inertia0.09 kgm²

Product weight1349 g

Type of mountingEither: With through-hole Via female thread

Pneumatic connectionM5

Note on materialsRoHS-compliant

Material drive shaftTempered steel

Material coverWrought aluminium alloy Anodised

Material sealsNBR TPE-U(PU)

Material housingWrought aluminium alloy Smooth anodised

|

In Stock

|

Subscribe

|

|

|

Size6

Cushioning angle0.5 deg

Swivel angle0 deg ... 90 deg

Permissible stop radius10 mm

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

Mode of operationDouble-acting

DesignVane

Position detectionVia proximity switch

Symbol00991265

VariantsSpigot shaft

Operating pressure0.35 MPa ... 0.8 MPa

Operating pressure3.5 bar ... 8 bar

Max. swivel frequency at 0.6 MPa (6 bar, 87 psi)3 Hz

Repetition accuracy1 deg

CE mark (see declaration of conformity)To EU Explosion Protection Directive (ATEX)

UKCA marking (see declaration of conformity)To UK EX instructions

Explosion protection certification outside the EUEPL Db (GB) EPL Gb (GB)

Explosion protectionZone 1 (ATEX) Zone 1 (UKEX) Zone 2 (ATEX) Zone 21 (ATEX) Zone 21 (UKEX) Zone 22 (ATEX)

ATEX category gasII 2G

ATEX category dustII 2D

Explosion ignition protection type for gasEx h IIC T4 Gb X

Explosion ignition protection type for dustEx h IIIC T120°C Db X

Explosion ambient temperature0 °C

|

In Stock

|

Subscribe

|

|

|

Moving mass for 0 mm stroke365 gAdditional moving mass per 10 mm stroke25 gProduct weight1684 gBasic weight for 0 mm stroke1216 gAdditional weight per 10 mm stroke78 gType of mountingVia female threadWith accessoriesEither:Pneumatic connectionG1/4Note on materialsRoHS-compliantMaterial coverDie-cast aluminium, coatedMaterial piston sealTPE-U(PU)Material pistonWrought aluminium alloyMaterial piston rodHigh-alloy steelMaterial piston rod wiperTPE-U(PU)Buffer seal materialTPE-U(PU)Cushioning boss materialPOMMaterial cylinder barrelSmooth-anodised wrought aluminium alloyMaterial nutGalvanised steelMaterial rod wiperTPE-EMaterial bearingMetal polymer compoundMaterial collar screwsGalvanised steel

|

In Stock

|

Subscribe

|

|

|

LABS (PWIS) conformityVDMA24364-B1/B2-LAmbient temperature-20 °C ... 80 °CImpact energy in end positions1.3 JCushioning length22 mmTheoretical force at 0.6 MPa (6 bar, 87 psi), return stroke1682 NTheoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke1870 NMoving mass for 0 mm stroke430 gAdditional moving mass per 10 mm stroke25 gBasic weight for 0 mm stroke1740 gAdditional weight per 10 mm stroke62 gType of mountingEither:Via female threadWith accessoriesPneumatic connectionG3/8Note on materialsRoHS-compliantMaterial coverDie-cast aluminium, coatedMaterial piston sealTPE-U(PU)Material pistonWrought aluminium alloyMaterial piston rodHigh-alloy steelMaterial piston rod wiperTPE-U(PU)Buffer seal materialTPE-U(PU)Cushioning boss materialPOMMaterial cylinder barrelSmooth-anodised wrought aluminium alloyMaterial nutGalvanised steelMaterial bearingPOMMaterial collar screwsGalvanised steel

|

In Stock

|

Subscribe

|

|

|

Size32

Cushioning angle1.4 deg

Rotation angle adjustment range0 deg ... 270 deg

Swivel angle0 deg ... 270 deg

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

Fine adjustment-6 deg

Mode of operationDouble-acting

DesignVane

Position detectionVia proximity switch

Symbol00991265

Operating pressure0.15 MPa ... 1 MPa

Operating pressure1.5 bar ... 10 bar

Max. swivel frequency at 0.6 MPa (6 bar, 87 psi)2 Hz

Operating mediumCompressed air to ISO 8573-1:2010 [7:-:-]

Corrosion resistance class CRC0 - No corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Cleanroom classClass 6 according to ISO 14644-1

Ambient temperature-10 °C ... 60 °C

Max. axial force75 N

Max. radial force200 N

Theoretical torque at 0.6 MPa (6 bar, 87 psi)10 Nm

Permissible mass moment of inertia0.025 kgm²

Product weight1425 g

Type of mountingVia female thread

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material drive shaftSteel Nickel-plated

Material sealsTPE-U(PU)

Material housingWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Size40

Cushioning angle16 deg

Rotation angle adjustment range0 deg ... 240 deg

Swivel angle0 deg ... 240 deg

CushioningShock absorber at both ends

Mounting positionoptional

Fine adjustment-3 deg

Mode of operationDouble-acting

DesignVane

Position detectionVia proximity switch

Symbol00991265

Operating pressure0.15 MPa ... 1 MPa

Operating pressure1.5 bar ... 10 bar

Max. swivel frequency at 0.6 MPa (6 bar, 87 psi)0.7 Hz

Operating mediumCompressed air to ISO 8573-1:2010 [7:-:-]

Corrosion resistance class CRC0 - No corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-10 °C ... 60 °C

Max. axial force120 N

Max. radial force350 N

Theoretical torque at 0.6 MPa (6 bar, 87 psi)20 Nm

Permissible mass moment of inertia0.11 kgm²

Product weight2800 g

Type of mountingVia female thread

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material drive shaftSteel Nickel-plated

Material sealsTPE-U(PU)

Material housingWrought aluminium alloy

Size40

Cushioning angle16 deg

Rotation angle adjustment range0 deg ... 240 deg

Swivel angle0 deg ... 240 deg

CushioningShock absorber at both ends

Mounting positionoptional

Fine adjustment-3 deg

Mode of operationDouble-acting

DesignVane

Position detectionVia proximity switch

Symbol00991265

Operating pressure0.15 MPa ... 1 MPa

Operating pressure1.5 bar ... 10 bar

Max. swivel frequency at 0.6 MPa (6 bar, 87 psi)0.7 Hz

Operating mediumCompressed air to ISO 8573-1:2010 [7:-:-]

Corrosion resistance class CRC0 - No corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Ambient temperature-10 °C ... 60 °C

Max. axial force120 N

Max. radial force350 N

Theoretical torque at 0.6 MPa (6 bar, 87 psi)20 Nm

Permissible mass moment of inertia0.11 kgm²

Product weight2800 g

Type of mountingVia female thread

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material drive shaftSteel Nickel-plated

Material sealsTPE-U(PU)

Material housingWrought aluminium alloy

|

In Stock

|

Subscribe

|

|

|

Ambient temperature-20 °C ... 80 °CImpact energy in end positions0.2 JCushioning length15 mmTheoretical force at 0.6 MPa (6 bar, 87 psi), return stroke158.3 NTheoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke188.5 NMoving mass for 0 mm stroke44 gAdditional moving mass per 10 mm stroke4 gBasic weight for 0 mm stroke186.8 gAdditional weight per 10 mm stroke7.2 gType of mountingWith accessoriesPneumatic connectionG1/8Note on materialsRoHS-compliantMaterial coverWrought aluminium alloyColourless anodisedMaterial sealsNBRTPE-U(PU)Material piston rodHigh-alloy stainless steelMaterial cylinder barrelHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

Stroke10 mm

Piston diameter32 mm

Piston rod threadM10x1.25

CushioningElastic cushioning rings/plates at both ends

Mounting positionoptional

DesignPiston Piston rod Cylinder barrel

Position detectionVia proximity switch

Symbol00991217

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Cleanroom classClass 6 according to ISO 14644-1

Ambient temperature-20 °C ... 80 °C

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke415 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke482.5 N

Moving mass130 g

Product weight384 g

Type of mountingWith accessories

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material coverWrought aluminium alloy

Material sealsNBR TPE-U(PU)

Material piston rodHigh-alloy steel

Material cylinder barrelHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

Stroke200 mm

Piston diameter32 mm

Piston rod threadM10x1.25

CushioningPneumatic cushioning, adjustable at both ends

Mounting positionoptional

DesignPiston Piston rod Cylinder barrel

Position detectionVia proximity switch

Symbol00991235

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Cleanroom classClass 6 according to ISO 14644-1

Ambient temperature-20 °C ... 80 °C

Cushioning length14 mm

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke415 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke482.5 N

Moving mass301 g

Product weight680 g

Type of mountingWith accessories

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material coverWrought aluminium alloy

Material sealsNBR TPE-U(PU)

Material piston rodHigh-alloy steel

Material cylinder barrelHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

Stroke25 mm

Piston diameter32 mm

Piston rod threadM10x1.25

CushioningPneumatic cushioning, adjustable at both ends

Mounting positionoptional

DesignPiston Piston rod Cylinder barrel

Position detectionVia proximity switch

Symbol00991235

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

Operating mediumCompressed air to ISO 8573-1:2010 [7:4:4]

Note on operating and pilot mediumLubricated operation possible (in which case lubricated operation will always be required)

Corrosion resistance class CRC2 - Moderate corrosion stress

LABS (PWIS) conformityVDMA24364-B1/B2-L

Cleanroom classClass 6 according to ISO 14644-1

Ambient temperature-20 °C ... 80 °C

Cushioning length14 mm

Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke415 N

Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke482.5 N

Moving mass144 g

Product weight410 g

Type of mountingWith accessories

Pneumatic connectionG1/8

Note on materialsRoHS-compliant

Material coverWrought aluminium alloy

Material sealsNBR TPE-U(PU)

Material piston rodHigh-alloy steel

Material cylinder barrelHigh-alloy stainless steel

|

In Stock

|

Subscribe

|

|

|

Stroke1 mm ... 500 mm

Piston diameter32 mm

CushioningElastic cushioning rings/plates at both ends Self-adjusting pneumatic end-position cushioning Pneumatic cushioning, adjustable at both ends

Mounting positionoptional

DesignPiston Piston rod Cylinder barrel

Position detectionVia proximity switch

VariantsExtended male piston rod thread Piston rod with female thread Custom thread on the piston rod Piston rod with male thread shortened at one end Extended piston rod Clamping unit on the piston rod Axial supply port With direct mounting Lateral supply port Metal scraper With protection against rotation High corrosion protection Dust protection Uniform, slow movement Low friction Through piston rod Heat-resistant seals max. 120°C Piston rod at one end

Protection against torque/guideSquare piston rod

Operating pressure0.1 MPa ... 1 MPa

Operating pressure1 bar ... 10 bar

Mode of operationDouble-acting

CE mark (see declaration of conformity)To EU Explosion Protection Directive (ATEX)

UKCA marking (see declaration of conformity)To UK EX instructions

Explosion protection certification outside the EUEPL Db (GB) EPL Gb (GB)

Explosion protectionZone 1 (ATEX) Zone 1 (UKEX) Zone 2 (ATEX) Zone 21 (ATEX) Zone 21 (UKEX) Zone 22 (ATEX)

ATEX category gasII 2G

ATEX category dustII 2D

Explosion ignition protection type for gasEx h IIC T4 Gb

Explosion ignition protection type for dustEx h IIIC T120°C Db

Explosion ambient temperature-20°C

|

In Stock

|

Subscribe

|

Unsubscribe

Subscribe